Unit 2-Bloodborne Pathogens

Methods of Compliance

Objectives:

After completion of this module, the learner will be able to:

"Universal" vs. "Standard" Precautions

Universal precautions are the methods identified by the Centers for Disease Control and Prevention (CDC) to prevent contact with blood or potentially infectious materials. The term universal precautions refers to treating all human blood, certain human body fluids, and other potentially infectious materials as if they are known to be infectious for HIV,HBV or other communicable pathogens. In the event that differentiation between body fluid types is difficult or impossible, all body fluids shall be considered potentially infectious materials.

Body substance isolation (BSI) or standard precautions is another method to control infection. This form of prevention defines all body fluids and substances as infectious. This method is a suitable substitute provisional on adherence to all other portions of the standard.

Now test your knowledge! You do not need a minimum score for any of the "Practice Time" Activities. These are to help review the material covered thus far!

Practice Time!

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

Engineering and Work Practice Controls

Engineering and work practice controls are required by the standard to be used by employers as the primary method to reduce or eliminate employee exposure. When considering engineering controls, these are utilized to reduce employee exposure by either removing or isolating the hazard or isolating the employee from exposure. Examples of engineering controls include self-sheathing needles, puncture-resistant containers for contaminated sharps disposal.

Work practice controls alter the method a task is completed to make the task safer. Prohibiting recapping, removing or bending needles unless no other exists; enforcing hand washing procedures following the removal of gloves, restricting eating and drinking in work areas; and decontaminating equipment before servicing are all examples of work practice controls.

If the exposure is still present after use of these controls, it is the responsibility of the employer to ensure employees are provided and use personal protective equipment as additional protection. The standard also recognizes that these two methods may be implemented together; that engineering controls may still need work practice controls.

Now test your knowledge! You do not need a minimum score for any of the DragNDrop activities. These are to help review the material covered thus far!

![]()

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

Hand Washing Facilities and Requirements

The standard requires readily accessible hand washing facilities for employee use. Hand washing must occur immediately after removing gloves or any other personal protective equipment that has become contaminated. The standard requires employers must make sure employees wash hands, other skin areas, or other mucus membranes with water immediately or as soon as possible following contact with body areas or other potentially infectious materials. Proper hand washing must be done with soap and running warm water. The purpose of proper hand washing immediately is to cleanse the skin of contaminated material.

If this is not feasible in certain areas, than waterless hand sanitizing stations are acceptable. According to the standard, in conjunction with these antiseptic hand cleaner stations should be clean cloth/paper towels or antiseptic towelettes. When this method is utilized, hands must be with washed with soap and running water as soon as possible.

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

Sharps and Needle Care

Needles and other sharps must not be bent, recapped or removed as stated by the standard. This is only acceptable if the employer can demonstrate that no other alternative is possible or that this is a required action by a specific medical or dental procedure. These actions must be completed via the use of a mechanical device or a one-handed technique. Shearing or breaking of contaminated needles is also prohibited by the standard.

Disposable sharps must be discarded into appropriate containers close in proximity and meet the following criteria: puncture resistant, labeled or color-colored according to the specifications identified in the standard, and leak proof on the sides and bottom. If the specimen is to be transported from the area of use, the container must be closed to prevent leakage. If leakage is possible, this initial container must be placed into a second container. A leak proof container must also be used in the collection, handling, processing, storage, transportation, or shipping of any blood or other potentially infected materials. The container for shipping, storage or transport mush be labeled or color-coded in accordance with the standard. In facilites that practice Universal Precautions during the handling of all specimens, it is not necessary to label or color-code provided the containers are recognizable as containing specimens. This is applicable to those specimens that are not leaving the facility. If the specimen is being shipped outside of the facility, normal labeling/color-coded as discussed above.

Reusable sharps such as, large-bore needles, scalpels and saws, must also be disposed of in containers that is puncture-resistant, labeled or color-coded as required, and leak proof on the sides and bottom. Employees are prohibited from putting their hands in the container. If reusable sharps must be cleaned for decontamination, work practices have to be incorporated to exclude the possibility of injury.

If an item is contaminated after exposure to contaminated blood or other potentially infectious material, it must first be examined before to servicing, shipping, and decontaminated as necessary. If the employer can demonstrate this is not feasible, the item must be labeled properly prior to servicing or shipping.

Now test your knowledge! You do not need a minimum score for any of the "Practice Time" Activities. These are to help review the material covered thus far!

Practice Time!

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

Surface Contamination

The standard prohibits employees from eating, drinking, smoking, applying cosmetics or lip balm, and handling contact lenses in work areas with the possibility of exposure. It is acceptable to use hand lotion/cream on thoroughly washed hands. Caution must be exercised when using some hand lotions. If the hand cream/lotion is petroleum-based, it may counteract with rubber gloves that will diminish the glove barrier protection.

Food and drink are not allowed to be stored in areas that the countertops or bench tops could be contaminated, nor in refrigerators, freezers, shelves or cabinets where blood or other potentially infectious materials are present per the standard requirements.

Mouth pipetting and suctioning

Mouth pipetting and suctioning are prohibited by the standard.

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

Personal Protective Equipment: General

If an employee has a risk of occupational exposure to blood or other potentially infectious materials still exists after the implementation of work practice and engineering controls, than personal protective equipment (PPE)must be used. Personal protective equipment refers to any type of clothing that prevents contaminated blood or other potentially infectious materials from passing through to the employees' clothes, undergarments, skin, eyes, mouth our other mucus membranes. This barrier must remain intact under normal work condition and the entire time it used. Personal protective equipment must be provided by the employer at no cost to the employee; it must be cleaned, laundered, disposed of, repaired and replaced at no cost to the employee.

It must be provided in accessible sizes and easily acceptable. Training must be done that explains the appropriate PPE use dependent on the exposure; where it is kept and how it is properly used.

An employee may determine the use of PPE would inhibit patient care and not use any form of PPE, under extenuating circumstances, in an emergent situation. If this occurs, the employer must investigate the incident and and document the circumstances surrounding the incident. The employer must also develop methods to prevent a recurrence.

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

Personal Protective Equipment: Clothing

Protective clothing barriers that prevent the spread of blood or other potentially infectious materials include gowns, masks, aprons, and other clothing. In situations where gross contamination can be reasonably anticipated, surgical caps or hoods, and/or shoe covers or boots must be worn. The employer determines the designation of PPE based on its function. The employer must evaluate the job task and the potential occupational risk of exposure, and thus identifies the appropriate PPE for the task. For example, lab coats or lab jackets may be sufficient in certain areas to act as PPE. The employer must provide employees with this determination and the employee must be trained in the selection of the appropriate PPE.

PPE provided by the employer must be removed by the employee prior to leaving the facility. The used PPE must be placed into the proper containers for storage, washing, decontamination or disposal. The employer is responsible for laundering, maintenance or disposal of protective clothing. The employee is to never take PPE home, under no circumstance.

If the personal protective equipment be penetrated by blood or other potentially infectious materials, it must be removed immediately. If it cannot be removed immediately, then it must be removed as soon as possible. The employee is responsible for washing the exposed area with soap and at a minimum, warm water as soon as the PPE is removed.

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

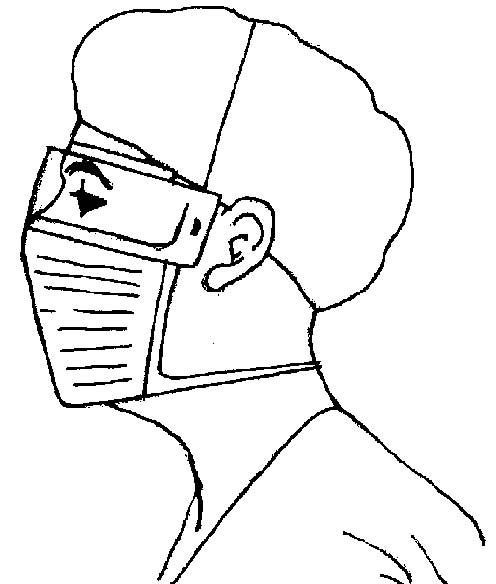

Personal Protective Equipment: Masks

The standard requires that blood or other potentially infectious materials related procedures be conducted in a method that reduces splashing, spraying, spattering and droplet generation. This serves two purposes: reduces the possibility of employee occupational exposure, and work area surface contamination.

Eye protection and a mask or face shield should be worn in those cases requiring aerosolization of blood or other potentially infectious materials. Masks, with incorporation of other eye protection such as goggles or glasses with a solid shield,or chin-length face shields are to be utilized when splashes,spray, spatter or droplets of blood or other potentially infectious materials may be produced and eye, nose, or mouth contamination is reasonably anticipated.

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

Personal Protective Equipment: Gloves

Gloves must be worn when contact with blood or other potentially infectious materials, mucus membranes or non-intact skin is anticipated. Included in the requirement for glove use includes vascular access procedures, handling and touching contaminated items or surfaces.

Single use gloves, also referred to as disposable, including surgical or examination, should be replaced as soon as practical when contaminated or as soon as possible if torn, punctured or when their ability to function as a barrier is comprised. They should not be washed or decontaminated for re-use.

An exception exists to routine gloving in volunteer blood centers for employees that perform phlebotomies. If the employer determines it is unnecessary to use gloves, then the employer must: periodically reevaluate the policy, make gloves available to all employees who wish to use them for phlebotomy and not discourage glove use. The employer must require use of gloves for the following: when the employee has cuts, scratches, or other breaks in his or her skin, when the employee judges that hand contamination may occur, and when the employee is receiving phlebotomy training.

Utility gloves may be decontaminated for re-use if the glove's integrity is not compromised. They must be discarded if cracked, peeling, torn, punctured or exhibit other deterioration or when the ability to function as a barrier has been compromised.

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

Personal Protective Equipment: Resuscitation Devices

Mouth-to-mouth resuscitation is not recommended and should be used minimally in only emergent situations. Another required component of PPE for employee use is ventilation devices that must be immediately accessible to employees that may be soundly expected to resuscitate patients. The type of resuscitation device is not specified. The employer chooses the appropriate and protective in normal situations the employee may encounter.

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

If you have any questions at any time regarding the information presented in this tutorial, please contact David Sullivan at 910-916-0688.

(North Carolina Department of Labor (2010). A guide to bloodborne pathogens in the workplace.)

At the completion of this module, please make sure to choose both "Email Score", and "Print Certificate". For compliance, please include your job title after your name. The completed report ("Email Score") is emailed to the OSHA Services coordinator for record keeping, and the printed certificate is for your personal records.

Move on to the next module, "Unit 3- Vaccination".